Pros and Cons of Chemical Grease Trap Cleaning Chemicals

Pros and Cons of Chemical Grease Trap Cleaning Chemicals

Grease traps play a vital role in any commercial kitchen. After all, slow drains and clogs are a nuisance—and stopping buildup from entering the sewer system is crucial to preventing both. But grease traps bring their own issues, whether they be foul odors, costly pump-outs, or disruptive maintenance. Chemical treatment can reduce these problems, but how do you know if it’s right for you?

At State Chemical, we manufacture and distribute chemical solutions for various purposes, including chemical grease trap maintenance. We know that your primary concern is whether chemical treatment will work for your grease trap, but it can be hard to weigh the merits and drawbacks.

To help you determine whether chemical maintenance is right for your grease trap, we will explain how it works and the pros and cons. After reading, you’ll know whether chemical maintenance is right for you.

How Do Grease Trap Cleaning Chemicals Work?

Chemical grease trap maintenance involves dispensing chemicals into your grease trap via a feed pump. Once in your grease trap, the chemicals break down fats, oils, and greases (FOGs) so they can pass easily through the pipes with the water. This then prevents FOG buildup and eventual clogs in your pipes and sewer system.

Grease trap maintenance products can either be bacterial or emulsifying. Bacterial products will build a colony in your drain, controlling FOG buildup by digesting it into water and air. Meanwhile, emulsifiers liquefy FOG buildup to help it pass easily through the drain with the water.

Bacterial products are more effective long-term solutions while emulsifying products offer a faster-acting initial solution. Either can be successful in your grease trap—it's just important to check your local laws before landing on a product, as emulsifiers are heavily regulated in many municipalities (this is because after FOGs are liquefied, they have the potential to resolidify further down the sewer line and cause problems for the city sewer system).

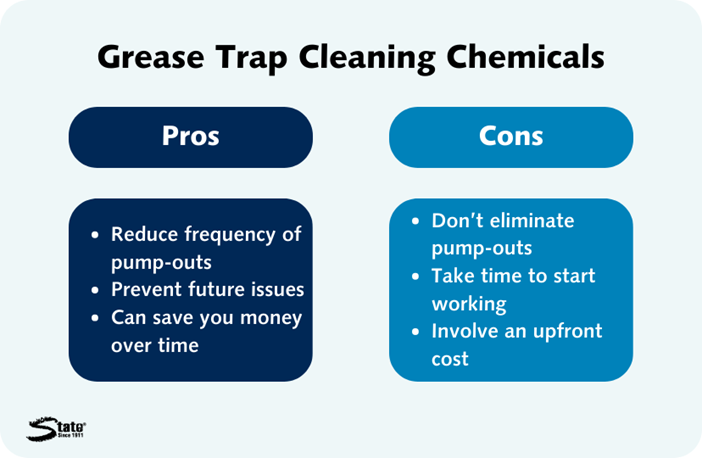

Whether or not to use a chemical grease trap maintainer depends on your specific situation, so it’s important to weigh the pros and cons.

Pro: Grease Trap Cleaning Chemicals Reduce How Often You Need to Pump the Grease Trap

All grease traps need to be pumped out. Many cities require commercial kitchens to pump out their grease traps at least once every three months.

To pump out a grease trap, your employees or an outside contractor must use specialized tools to remove the FOGs from the system. From there, they wash and scrape any remaining grease off the equipment and properly dispose of all materials collected.

A significant benefit of chemical preventative maintenance is that it reduces the number of times per year that you need to pump out your grease trap. For example, through chemical maintenance, many facilities can reduce their pump-outs from once every month to once every three months. This can save you money, time, and the headache of frequent facility disruptions.

Con: Grease Trap Cleaning Chemicals Don't Eliminate Grease Trap Pump-Outs

It’s important to realize that while adding chemical preventative maintenance reduces the frequency of grease trap pump-outs, it does not eliminate them. As previously stated, many cities legally require kitchens to pump out their grease traps. And even if they don’t, the grease trap is going to collect a lot of FOGs over the course of a few months. Chemicals can break down a good amount of these FOGs, but eventually, the FOG influx will be too overwhelming, and a pump-out will be needed.

Since pump-outs are necessary regardless, some facilities prefer to deal with more frequent pump-outs rather than also handle chemical maintenance. After all, if pump-outs are necessary either way, some facilities may not see a need to get involved in additional maintenance.

Meanwhile, others prefer to use chemicals if it means less frequent pump-outs. Either choice can effectively maintain a grease trap; it all comes down to personal preference.

PRO: Grease Trap Cleaning Chemicals Prevent Future Problems

A significant benefit of adding chemicals to a grease trap is that they can prevent future problems. If a grease trap is untreated and not pumped out, it can overflow, causing an odorous, greasy mess in your kitchen. Even if this worst-case scenario doesn’t happen, untreated grease traps emit a pungent smell that can attract flies and cockroaches. Moreover, when grease traps get too full, FOGs are more likely to accidentally flow into the sewer system. This can unintentionally lead to buildup and clogs.

When you use a chemical grease trap maintainer, these risks are reduced significantly. Grease trap maintenance keeps FOGs under control, and without an excess of FOGs, there will be considerably less buildup and odors.

In this way, chemical grease trap maintenance can keep the system cleaner and make it less likely to experience problems. Pump-outs, if done consistently enough, can do the same, but chemical maintenance offers an additional protective cushion that gives facilities peace of mind.

Con: Grease Trap Cleaning Chemicals Take Time to Start Working

Chemical grease trap maintenance reduces the FOG buildup in a grease trap. However, this is not an overnight fix.

With emulsifying products, this can be a quicker change, but for facilities that use bacterial products to maintain their grease traps, the bacteria will need time to grow their colony. This involves the bacteria entering the grease trap, activating, feeding on FOGs, and reproducing. Until the bacteria establish their presence in your grease trap, significant changes won’t be evident. Most kitchens won't see the full results of bacterial grease trap maintenance for about three months.

This varies by situation, and the time period can be reduced if emulsifying products are used instead. However, if you’re looking for an immediate fix, you should probably schedule a pump-out rather than start chemical maintenance.

Pro: Grease Trap Cleaning Chemicals Can Save You Money Over Time

Many facilities turn to chemical grease trap maintenance because it can be a cost savings compared to more frequent pump-outs. Generally, pump-outs can cost you roughly $3,900–$12,480 per year if you pump out every month. Meanwhile, chemicals and less frequent pump-outs (every three months) can cost you roughly $2,980–$8,960 per year. This means chemicals offer a median cost savings of $2,220 per year.

Of course, this depends greatly on your situation, with factors like FOG severity, quantity of chemicals used, grease trap condition, and grease trap size significantly influencing the price. But based on your situation, chemical grease trap maintenance will often save you money.

CON: Grease Trap Cleaning Chemicals Involve an Upfront Cost

Although chemical grease trap maintenance can save you money in the long run, it does involve an upfront charge. For example, a grease trap maintenance program with State Chemical costs $150–$400 per month. This can be feasible for some facilities as an alternative to more frequent pump-outs, but for others, it may not be in the budget, especially as pump-outs will still be frequent before the chemicals take full effect.

Depending on your situation, you may prefer to deal with a higher upfront cost (chemicals) or a higher end cost (more frequent pump-outs). This is entirely based on your situation and individual preferences.

Learn About How State Chemical's Line Bac'r Can Treat Your Grease Trap

A grease trap is the employee that your facility needs every day for things to operate smoothly. As a result, you want to keep it in proper working order. Now that you know the pros and cons of chemical grease trap maintenance, watch the video below to learn how State Chemical’s Line Bac’R can help you treat your grease trap.