How to Reduce H₂S Sewer Gas

How to Reduce H₂S Sewer Gas

Hydrogen sulfide (H₂S) is not the type of thing you want lurking in your wastewater collections system. It smells like rotten eggs—enough to make anyone’s stomach turn. It’s flammable and hazardous, with the potential to deteriorate concrete and corrode iron and steel. And to top it all off, when it reaches high levels, it can be fatal.

At State Chemical, we manufacture and distribute chemical solutions to various problems, including H₂S in sewers and lift stations. No one wants H₂S in their sewer lines, but since it’s impossible to fully eradicate, treating it can feel like a losing battle—and you shouldn’t have to deal with that.

To help you determine the best method of H₂S treatment for your needs, we will explain the causes of H₂S, what it means to treat H₂S with calcium nitrate, what it means to treat H₂S with bacteria, and which method is right for you. After reading, you’ll know what product you need to handle your H₂S problem.

What Causes H₂S Sewer Gas?

In sewers and lift stations, H₂S gas naturally occurs, formed through the breakdown of organics by microorganisms called biofilm. When the bacteria in the biofilm break down organics, they produce a substantial amount of H₂S as a byproduct.

Within sewer and lift station settings, there is an abundance of organic breakdown occurring, and because of the anaerobic conditions (meaning that there is very little oxygen present), H₂S thrives.

Additional factors that encourage H₂S formation include turbulent water flow, stagnant water or slow wastewater flow, depletion of nitrates, abundance of sulfates, and warm wastewater. Unfortunately, lift stations and sewers frequently see most or all of these conditions, and once H₂S is trapped in these small spaces, it can become deadly.

H₂S is already undesirable for its natural odor, but more than anything, it can be dangerous even in low concentrations. Slight levels of H₂S have been known to cause eye and throat irritation, headaches, dizziness, nausea, and coughing. High levels of H₂S can cause difficulty breathing, impaired motor ability, loss of consciousness, and even death.

These effects can set in very quickly (especially because when H₂S is very strong, it paralyzes nerves, resulting in a loss of smell that renders it indetectable to the senses), so it is of the utmost importance to follow safety protocol and keep your H₂S levels under control.

As previously mentioned, H₂S cannot be completely eliminated from your lift station or sewer; it occurs naturally with the breakdown of organics, so it will always be there. However, there are ways to keep H₂S at a safe level for the well-being and comfort of your facility.

How to Reduce H₂S with Calcium Nitrate

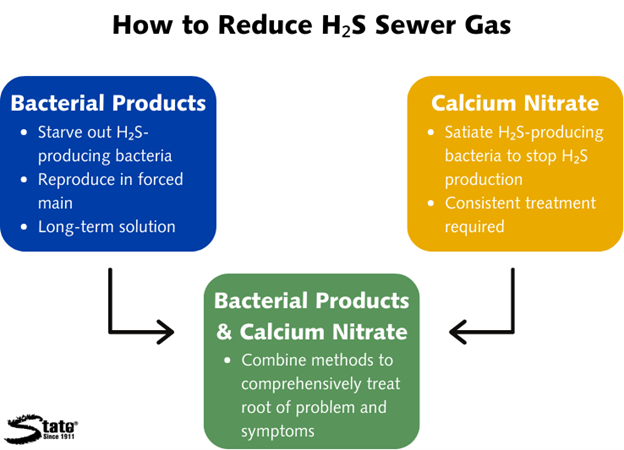

The most common method of reducing H₂S gas is through calcium nitrate products, such as BIOXIDE®. Calcium nitrate works by feeding the sulfate-reducing bacteria or SRB (the microorganisms that produce H₂S) to keep them satiated, meaning they don’t produce H₂S. They are given a different oxygen source so they cannot chemically produce H₂S.

With calcium nitrate, H₂S production levels are reduced through this SRB satiation. This is a great treatment method for stopping H₂S production before it can begin.

However, it’s important to note that with this method, you will need to keep feeding calcium nitrate to your SRB indefinitely, and you may need to increase your dosage over time in order to keep up with potential SRB growth.

How to Reduce H₂S with Bacterial Products

Your other option for reducing H₂S gas is with bacterial products (using “good” bacteria). As opposed to calcium nitrate, bacterial products reduce H₂S by outcompeting SRB for the same food source.

This starves out the SRB, who no longer have a sufficient food source, and when there are fewer SRB, there is less H₂S being produced in the first place. Once your bacterial product is present, the “good” bacteria continue to reproduce in the forced main and outcompete the SRB.

This means that the biofilm will be kept at bay, and the H₂S output will be significantly reduced by the good bacteria. Compared to calcium nitrate, bacterial products are considered to better treat the root of the problem, making them an ideal long-term solution.

Additionally, bacterial products can be used at the same time as calcium nitrate as a way of treating the problem more comprehensively.

Which H₂S Treatment Method is Right for You?

Either method of H₂S treatment can be effective in your facility. It just depends on how you want to approach the problem.

For immediate results that stop H₂S from being produced, use calcium nitrate. Just keep in mind that this will be a product that you have to feed to your biofilm consistently in order to yield effective results.

To reduce H₂S and outcompete SRB, use bacterial products. This is a way to directly reduce the source of H₂S and act as a long-term solution since even if you stop using the product, the good bacteria already present will continue growing their colony. Plus, it is usually less costly than calcium nitrate.

If you would like to accelerate the results of either method, use both in tandem. This way, you can control H₂S production, outcompete SRB, and prevent future growth. While it will cost more, this is the most comprehensive solution to persistent H₂S problems.

Learn About How State Chemical Can Help with H₂S Reduction

H₂S gas isn’t the sort of thing you want to mess around with, but when it’s impossible to fully eliminate, it can be challenging to find the right solution. Now that you know how calcium nitrate and bacterial products can help you control your H₂S, watch the video below to learn how State Chemical’s Pit Raider and Nutri Pro can help you with H₂S reduction.