Commercial Drain Chemical Safety: Problems and Solutions

Commercial Drain Chemical Safety: Problems and Solutions

When it comes to drain chemicals, most people feel a bit of apprehension or concern. The word “chemical” itself brings to mind label warnings with a skull and crossbones. They can be an intimidating thing, but when it comes to your drain care, the best way to protect yourself and your staff is to be educated about chemical safety.

In business since 1911, State Chemical has encountered concerns about chemical safety for over a hundred years. The desire to protect your staff is real and absolutely valid, and we will help you accomplish that.

Therefore, we’ve taken the time to consider problems with drain chemical safety and provide solutions that will put you in the best place to protect your staff. In this article, we’ll cover the following:

- Safety when handling acids

- Safety when handling heat-generating drain openers

- The impact of chemicals on pipes

- Avoiding chemical splash back

- Protecting yourself from chemical fumes

- Preventing chemical contamination

Problem: Acids are Dangerous to Handle

The most intimidating drain chemical is the most dangerous one: acid. When the options are laid out for you, you’re probably the most apprehensive about acid. Sure, it’s effective with severe drain clogs, but you may be worried about even getting it down the drain.

Acid shouldn’t be used unless you’re experiencing severe drain blockages, and if you’re in that situation, you may be rightfully concerned about handling it. With the potential to burn through clothes, shoes, skin, cotton, plastics, and more, it’s no surprise that acid can cause severe chemical burns.

Solution: Wear PPE, Use Product as Directed, and Educate Your Staff

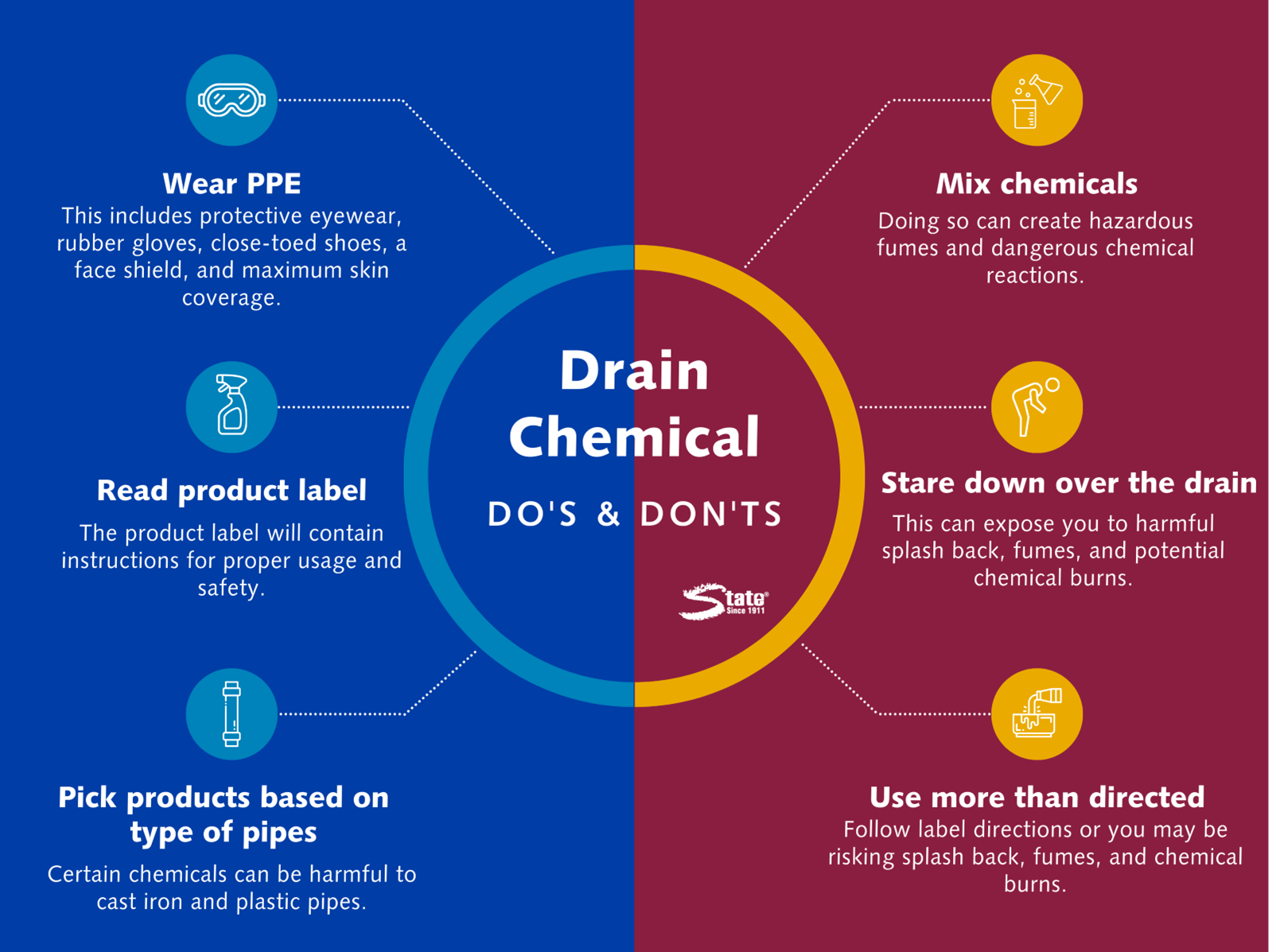

The best thing you can do to protect yourself from acid injuries is to wear personal protective equipment (PPE). This includes protective eyewear (meaning safety goggles or glasses intended for chemical protection), nitrile or rubber gloves, work boots, a face shield, and chemical-resistant clothing. Unless you spill the product all over yourself, PPE will go a long way in protecting you from accidental exposure.

Similarly, it’s just as important to read the label before using the product to ensure that you’re following all directions. The product label will be able to give you more specific information on how to handle your particular acid so that you can keep yourself and your staff safe.

Lastly, it’s important to educate the staff themselves about safely handling acid. If you expect them to figure it out themselves, they may overlook an important step of the process and end up getting hurt. Teach your staff proper handling beforehand to prepare them for when they’re in the situation. Resources such as this informative OSHA poster can help you to keep your workers safe and informed, and you’re also legally required to provide this kind of education.

Problem: Heat-Generating Drain Openers Can Cause Chemical Burns

A similar concern to the safety of acid is the safety of heat-generating drain openers. While generally safer than acids, it’s true that heat-generating chemicals can also cause chemical burns if mishandled.

Solution: Wear PPE, Read Product Directions, and Educate Your Staff

So, how do you deal with this risk? The same way you deal with acids: wear PPE, read product directions, and educate your staff.

Just as with acids, PPE will involve protective eyewear, work boots, nitrile or rubber gloves, and maximum skin coverage.

Meanwhile, proper handling means reading the product label and using the directed amount of product. Often, chemical burns from heat-generating drain openers occur when people use too much product, causing splash back and other hazards. Use products as directed and educate your staff to do the same to keep your facility safe.

Problem: Chemicals Can be Harsh on Pipes

Another common concern is that drain chemicals may cause damage to your pipes. This can be true: when putting harsh chemicals down your drain, you can wear out your pipes, but this isn’t true in all cases. It depends on your pipes and the specific chemicals you use.

Solution: Use the Best Product for Your Type of Pipe

To avoid damage to your pipes, you need to use the proper chemical based on your type of pipe.

If your building was built before 1980, you likely have cast iron pipes, which tend to deteriorate after about twenty-five years. With cast iron pipes, you’ll likely be dealing with rust and corrosion, so it’s best not to use acid in these situations or you might blow through weakened parts of your pipes. It depends on the issue’s severity, but heat-generating chemicals shouldn’t usually cause harm to cast iron pipes.

If you have plastic pipes, like PVC or ABS, acids can melt through them and not all heat-generating chemicals are safe to use. Read product labels for correct usage and when not to use them.

The least worrisome kind of pipe when using drain chemicals is a healthy metal pipe that shows no signs of deterioration. If you have healthy metal pipes, drain chemicals will not cause damage if used as directed. So, acids, heat-generating drain openers, biologicals, and anything else are a go.

Problem: Chemical Splash Back is Dangerous

Another concern you may have is regarding the possibility of chemical splash back. When you put a drain opener down your drain, it is possible for the chemical to hit the clog and have a violent reaction, which can cause dangerous chemicals to splash back at you as the user. Especially if the clog isn’t very far down the drain, this is a very real risk, and you could end up with chemical burns.

Solution: Stand a Safe Distance from the Drain

To avoid this outcome, it’s important to follow label directions, wear PPE, and stand a safe distance from the drain. After you put the chemicals down your drain, take several steps back and wait fifteen minutes (or the directed time on the product label) before checking the drain again. You should never look directly over the drain to see if the product is working. If you get chemicals in your eyes, it’s critical to have access to and know how to use a chemical eye wash station.

Problem: Chemical Fumes are Hazardous

When you’re in a closed room with a drain chemical, you’re likely going to be worried about the fumes. You don’t want to breathe in anything that’s going to hurt your lungs, and chemical fumes can have harmful effects when inhaled.

Solution: Stay a Safe Distance from the Drain and Don’t Mix Chemicals

For the fumes of a single chemical, it’s a good idea to stay a safe distance from the drain. After using the chemical, it’s best to leave the room for the recommended amount of time before checking to see if the chemical worked. This way, you can avoid breathing in any chemical fumes. We recommend doing your drain treatments at the end of the day if you’re able so that you can leave directly after and avoid inhaling chemical fumes.

The other important part of protecting yourself from hazardous fumes is to never mix chemicals. If you’ve used other chemicals in your drain recently, the new chemical you pour down could have a reaction with the other chemicals, creating hazardous fumes.

Be sure to keep track of what’s going down your drains so that you can make sure the chemical you use doesn’t react with others you may have used recently. If you’ve used another chemical recently, flush hot water down your drain and wait at least several days before using a new product.

Problem: Chemical Contamination Could Put My Staff at Risk

Another concern you may be facing is the possibility of contamination. If you’re now storing a hazardous chemical in your facility, can’t it now contaminate surfaces and cause accidental harm to staff or customers? This could happen, but that’s why it’s important to educate yourself on proper storage.

Solution: Safely Store Half-Used Bottles

So, what does safe chemical storage look like?

Well, if you’re saving a bottle you’ve already opened, it’s first important to make sure the lid is properly screwed and tightened to prevent leakage. From there, it’s also important that you keep the chemicals in their original bottle unless directed otherwise. If you switch them between containers, you risk additional contamination since not all containers are suited for certain chemicals. Additionally, the process of switching the chemical to another container could cause harmful exposure to the user.

By keeping the chemical properly closed in its original bottle, you significantly lower the risk of harmful contamination to your facility.

Your Next Step: Educate Your Staff

Figuring out how to properly handle a drain chemical can be intimidating. It’s hard to understand what’s okay versus what’s harmful, and at the end of the day, you want to run a safe facility. Now, you know solutions to common drain chemical safety problems, and you’re ready to think about which product is the best fit to unclog your drain.