How to Choose the Right Chemical Dilution System for My Facility

How to Choose the Right Chemical Dilution System for My Facility

Most people don’t know what the term “chemical dilution system” even means, so when you’re searching for the right one for your facility, you might feel out of your element. All you know is that you’d like to safely and easily use your cleaning chemicals while saving product. But what system do you need to accomplish this?

At State Industrial Products, we manufacture and distribute chemical solutions for a variety of problems, and one of our primary products is One Solution™, a chemical dilution system. We know that it can be challenging to determine what system you need when you aren’t already acquainted with dilution systems, so it’s our goal to give you honest information to help you make an informed decision.

In this article, we will explain what a chemical dilution system is, factors in your facility that will influence your choice, and how to ultimately choose the right system for you. After reading, you’ll know what kind of chemical dilution system will perform best in your facility.

What is a Chemical Dilution System?

First, it’s important to understand what we mean by “chemical dilution system.” A chemical dilution system is a dispenser that dilutes a concentrated cleaning product with water. Then, it dispenses the product at a pre-determined ratio so that you can safely use it in your facility.

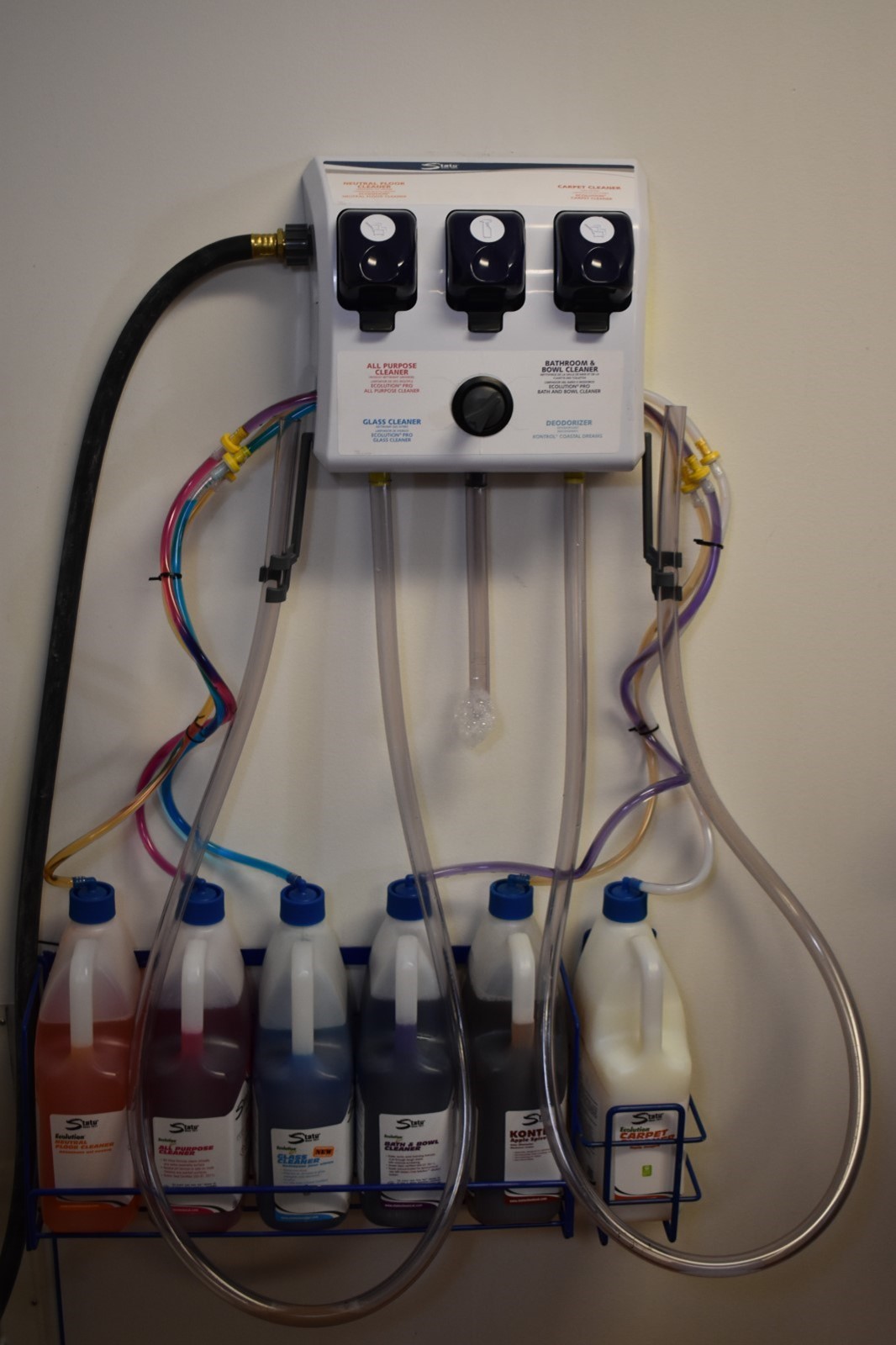

Depending on the type of system you get, chemical dilution systems can be used for floor cleaners, glass cleaners, all-purpose cleaners, disinfectants, degreasers, and more. From there, they can dispense chemicals into spray bottles, mop buckets, or larger equipment (e.g., carpet extractors).

Because the system pre-mixes the solution, you don’t have to worry about the labor or hazard of hand mixing your chemicals. Additionally, results will remain consistent since the mixing ratio will always stay the same.

Overall, chemical dilution systems streamline the chemical dispensing process, ensure handling safety, and keep products consistent.

How Many Cleaning Products Do You Want in Your Dilution System?

To determine which system will perform best in your facility, you must first consider how many products you want to consolidate into one dilution system.

For example, let’s say that you currently use pre-mixed floor cleaner, disinfectant, and glass cleaner. You want to switch to a dilution system for these three products, so you’ll need to find one that will support at least three different chemicals. This way, you can most efficiently consolidate your chemicals rather than having multiple redundant systems.

Meanwhile, if you only wanted a dilution system for your disinfectant, you’ll want to find a system specifically designed to support one chemical. While you could technically use a larger system, the extra space would be an unnecessary expense.

Know what chemicals you’re interested in adding to a system in advance. This will make your search easier and your eventual dilution system more efficient.

What is the Intended Location for Your Chemical Dilution System?

Next, think about where you want to place your chemical dilution system.

Chemical dilution systems need a water source in order to function, so you’ll need to pick a place in your facility with access to water. Otherwise, your only limit is the size of the area compared to the size of the system.

Common usage areas include three-compartment sinks, storage closets, backrooms, and under counters. Usually, what you want your system to do will heavily influence where you locate it.

For example, if you want to fill mop buckets, it would make sense to have your dilution system in a storage closet with the mop. Meanwhile, if you want to quickly disinfect glasses at a bar, having your system under the counter would make sense.

If you have a specific area in mind, make sure that you have room for the system you’re interested in. A system with four different chemicals may not fit in your already-crammed supply closet, and having enough space is essential to having a helpful system.

What is the Intended Application for Your Chemical Dilution System?

Similarly, it’s important to consider what you want to be using your dilution system for. You may know that you want to dispense a disinfectant from your backroom, but do you want it in spray bottles, mop buckets, or other equipment?

Understanding the specifics of your goal will help you plan out which system will work best for you. Pay close attention to your intended dilution system’s capabilities to ensure you’re purchasing one that can do the work you anticipate. Different applications will require that the chemicals are dispensed differently, and this changes the type of system you will buy.

Choosing the Right Dilution System for You

Overall, choosing the correct chemical dilution system really comes down to what your objectives are and what your facility’s needs are. There is no wrong system unless it doesn’t align with your goals. For multiple purposes, you can even use multiple systems—it all depends on your situation.

Choose the chemical dilution system that fits your needs, and your efficiency will benefit.

Learn About State Industrial Products’ One Solution System

It can be challenging to find the right chemical dilution system when you aren’t already familiar with them. Now that you know how to determine what the best dilution system is for you, consider learning about State Industrial Products’ dilution system, One Solution.