Common Questions About Chemical Dilution Systems

Common Questions About Chemical Dilution Systems

Picture this: you’re the head custodian of an elementary school. Every week, the floors need cleaned, the desks need sanitized, the bathrooms need scrubbed down, and more. It gets to be overwhelming—even more so when you’re constantly going through cleaning products and having to keep track of what you need more of and when you need it. This is the way it’s always been, but it really takes the energy out of you. Is there even any way you can make this easier?

At State Industrial Products, we manufacture and distribute a variety of chemical solutions and systems, including One Solution™, our chemical dilution system. Managing an array of different chemicals can be a surprising kind of hassle, but getting clear answers about dilution systems can be just as hard.

To teach you about chemical dilution systems, we will explain what they are, common questions people ask about them, and answers to those questions. After reading, you’ll know if chemical dilution systems are the solution to your problem.

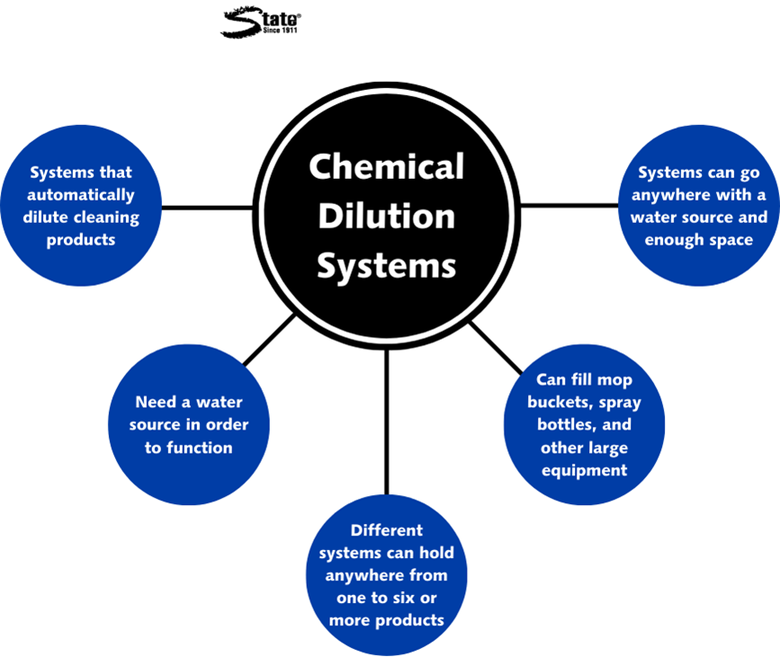

What is a Chemical Dilution System?

A chemical dilution system is an automated system that dilutes and dispenses a cleaning product at the correct ratio. Dilution systems consolidate products into a single machine, allowing each to fill a container without coming into contact with the user.

These systems can be used for floor cleaners, glass cleaners, carpet cleaners, bathroom cleaners, all-purpose cleaners, degreasers, disinfectants, sanitizers, and more. It all depends on the exact system you purchase, but generally, these are the types of products you can expect to choose from.

How Do Chemical Dilution Systems Work?

Chemical dilution systems function through a water source and tubing. You push a button, and it creates a vacuum that mixes the concentrated chemical with the correct dilution of water. Then, your cleaning product dispenses through a short hose (for spray bottles) or a long hose (for mop buckets and other large equipment, such as a pressure washer).

Many of these systems use a special piece called an eductor, which prevents backflow that would otherwise put contaminants into the water supply. Overall, this setup creates a safe, contact-free experience for the user.

How Many Products Can a Chemical Dilution System Hold?

A chemical dilution system can hold a different number of products based on the exact system you select.

For example, you can buy a system that just dispenses one cleaning product. This might be good for a storage closet, for instance, where you only want the ability to use a floor cleaner for mopping. However, you could also purchase a system that dispenses six different cleaning products, which would be handy if you consistently use many different cleaners.

The number of products your system can dispense really depends on the system you choose. Look for a system with your desired capacity, and you’ll have a range of options.

What Applications Do Chemical Dilution Systems Have?

Some people want chemical dilution systems to fill mop buckets; others want chemical dilution systems to fill spray bottles. Some people even want these systems to fill larger equipment, such as scrubbers, carpet extractors, or pressure washers. All of these applications and more are possible with chemical dilution systems.

How you want to dispense your cleaning products will change the way your system is set up. For spray bottle applications, your system will use short hoses. For buckets or larger equipment, your system will use long hoses. Your system may also use a combination for different chemicals that you intend to apply differently.

All in all, chemical dilution systems have variable applications based on your desired use.

Where Can I Put My Chemical Dilution System?

Your main restrictions with a chemical dilution system are how much space is available and whether there is access to a water source.

For example, your ideal location for your dilution system might be a storage closet, but if it doesn’t have access to a water source, it won’t work. Conversely, you might have a backroom with access to a water source but no space to conveniently place the system. These situations can be frustrating obstacles to a situation that would otherwise work great for you.

Before investing in a chemical dilution system, be aware of which areas of your facility do and do not have access to water sources. From there, plan how to arrange the system to fit in your space if it’s currently crammed. Unfortunately, handheld cleaners may be a better solution when you don’t have the room or the water source, but in most cases, a solution can be found.

How Much Do Chemical Dilution Systems Cost?

One of your main concerns when making any purchase is the cost—and rightfully so. With dilution systems, the cost varies by company and model. Many companies do not publicly disclose the prices of their chemical dilution systems, and it wouldn’t be ethical for us to disclose these prices. Instead, we will provide you with the example of One Solution™, our chemical dilution system.

One Solution is provided on a supply agreement, which is paid through monthly bills based on product usage. Usually, mop buckets will be $5.00–$10.00 per fill and spray bottles will be $0.50–1.00 per fill. This is factored into your yearly agreement, which generally costs a total of $X and will be paid monthly.

The upfront cost of chemical dilution systems may have a higher price tag, but the end cost is significantly lower compared to handheld products (usually $5.00–$40.00 for a mop bucket fill and $2.00–$10.00 for a spray bottle). Consider the value of a lower end cost to determine if chemical dilution systems are right for you.

Learn How to Choose the Right Chemical Dilution System for Your Facility

When you’re working with several different cleaning products at once, it can be challenging to manage everything without feeling a bit overwhelmed. Chemical dilution systems are a way to consolidate products and simplify the process—all while making chemical handling safer.

To continue exploring chemical dilution systems, read this article about how to choose the right chemical dilution system for your facility.