Chemical Dilution Systems vs. Handheld Cleaning Products

Chemical Dilution Systems vs. Handheld Cleaning Products

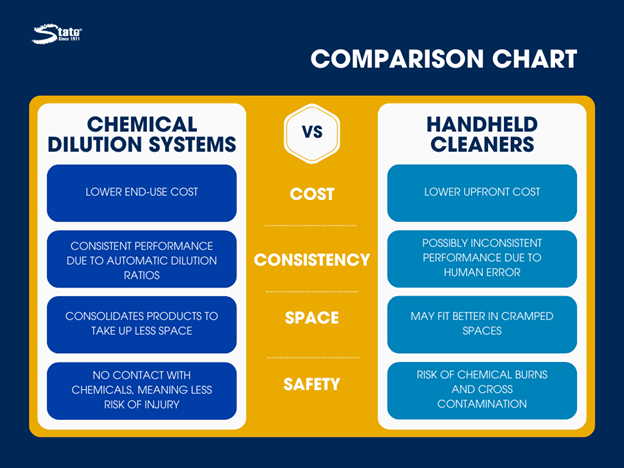

We often stick to what we’re familiar with; it’s more comfortable to deal with something we already know. This goes for cleaning products too. So, we use spray bottles and gallons, mixing by hand when called for and buying more when the bottle runs out. We get so used to these routines that sometimes, we might not even realize other options exist. But they do, and chemical dilution systems can actually provide many benefits compared to handheld products.

At State Industrial Products, we manufacture and distribute various categories of chemical solutions, including One Solution™, our chemical dilution system. Handheld products can be a hassle to keep up with, different products constantly being in different states of requiring replacement, but you may not be immediately familiar with your alternative options.

To help you determine which option is best for you, we will explain chemical dilution systems, handheld cleaning products, and the benefits of each. After reading, you’ll know which option is best for you.

What is a Chemical Dilution System?

First, it’s important to understand what a chemical dilution system is. Chemical dilution systems are devices that automatically dilute chemical products at a pre-determined rate. From there, they allow users to safely dispense the cleaning product into a spray bottle, bucket, or another piece of equipment.

Depending on the type of system, they can be used for products like floor cleaners, glass cleaners, disinfectants, sanitizers, and more. Dilution systems can also be used to consolidate products, meaning that a single system can hold as many products as its design allows (usually between one and six).

What is a Handheld Cleaning Product?

In contrast, a handheld cleaning product is the usual spray bottle or bucket of chemicals that you probably think of when you hear the word “cleaner.” Handheld cleaning products will either come ready-to-use or will need to be manually mixed with water to the correct dilution ratio. Most, if not all, cleaning products will be offered in this form.

Chemical Dilution Systems Have a Lower End-Use Cost

One of the main benefits of chemical dilution systems is that they have a lower end-use cost than if you were to continually buy handheld cleaners.

When you consistently buy handheld cleaners, you’re buying the same bottle repeatedly. At first, spending $10 on an industrial cleaning spray doesn’t seem like a big deal. However, if you finish this product bi-weekly, that’s $260 a year for a single chemical product.

Meanwhile, a dilution system will cost you about $0.50–$1.00 per spray bottle and $5.00–$10.00 per five-gallon mop bucket. If you finish them bi-weekly as with the cleaning spray, the spray bottle would cost $13–$26 per year, and the bucket would cost $130–$260 per year. The initial price tag of this year-end cost may not seem like a savings, but after a long period of time, the difference is stark.

Handheld Cleaning Products Have a Lower Upfront Cost

However, the reality is that sometimes, you need a lower upfront cost. Maybe your budget is tight right now, or you aren’t sure of how frequently you’ll use certain products. In these cases, the lower upfront cost of handheld products will probably be more appealing. A good example of this would be if you use one bottle a month of a daily cleaner that costs $5.00 from the local store.

Chemical Dilution Systems Offer Consistent Performance

One of the best benefits of using chemical dilution systems is that they have consistent dilutions that deliver consistent performance. The machine automatically dilutes the chemical to the correct, consistent ratio to work most effectively. Day after day, you will get the correctly diluted product to get the job done.

Meanwhile, when you manually dilute your chemicals, there’s a much higher margin of error. Different employees could assume they should use different ratios, leading to inconsistent performance. You could accidentally overfill the water, making the product too weak. Someone could mistakenly use the straight concentrate, causing a safety hazard.

We’re only human, and we make mistakes. With dilution systems, the possibility of these mistakes is lowered tremendously.

Chemical Dilution Systems Consolidate Cleaning Products

If you use a lot of different cleaning products in your facility, chemical dilution systems can help to consolidate these products. This way, you only have to manage everything from one system, taking up less space and making it easier to order more inventory as needed.

Chemical dilution systems can also be used to consolidate fewer products (you can even use them for just a single product), which can be useful for quick dispensing and consistent dilution. However, they are usually most appealing for chemical consolidation since this makes a more significant difference for most facilities.

Some Handheld Cleaning Products Take Up Less Space

Something to consider is where you want to store your chemicals. In some instances, chemical dilution systems can save space through consolidation. In others, handheld cleaning products might be more efficient for your space.

Consider a cramped storage closet. In some cases, the right dilution system will fit just right. In others, the system might be too bulky for the closet setup and shape. In these types of situations, it would make more sense to invest in handheld products that you can store in a way that works with your setup.

Chemical Dilution Systems are Generally Safer to Use

When it comes to mixing chemicals, you’re generally much safer if you don’t have to mix by hand. With manual mixing, there is the risk of accidental contact, spillage, and cross-contamination between chemicals. These mistakes can lead to chemical burns, the creation of dangerous fumes, and more undesirable reactions.

With chemical dilution systems, the process of mixing is done by a dispenser, so the risk to your facility is reduced to almost zero. Meanwhile, with manual mixing, accidents happen, and that can have serious implications for your facility.

Chemical Dilution Systems Require Less Work

Because of the automatic dilution, chemical dilution systems also mean less work for you. You won’t have to dilute the chemicals by hand, and if you get your system on a supply agreement, you won’t have to worry about ordering new chemicals or replacing them in the dispenser. Automated systems make for automated experiences, which can be a helpful benefit when you’re already busy running a facility.

Handheld Cleaning Products Make More Sense for Infrequent Needs

It makes the most sense to use handheld cleaning products when you have few and/or infrequent cleaning needs. All facilities need to be cleaned, but maybe you run a seasonal store that only needs products two months out of the year. Maybe you own a small local bookstore that just occasionally cleans its bathrooms and windows. In cases like this, a dilution system just wouldn’t make much sense.

Instead, handheld products make sense for infrequent applications, as they can be purchased on an as-needed basis, which will probably be more cost-effective.

Learn How to Choose the Right Dilution System for Your Facility

When you’re more familiar with handheld cleaning products, it makes sense to stick with them, but chemical dilution systems are a hands-off, consistent solution for those who need one. Now that you know whether chemical dilution systems are right for you, continue learning about them by reading about how to choose the right system for your facility.