Chemical Dilution Systems: Pros and Cons

Chemical Dilution Systems: Pros and Cons

A clean facility is a happy facility, but it doesn’t happen with a snap of the fingers. Keeping your location clean is hard work, often involving many different cleaning products that require constant restocking. This can be taxing, but will a chemical dilution system be any better? Everything has pros and cons, and you need to look out for your business.

At State Chemical, we manufacture and distribute a variety of chemical solutions, including One Solution™, our chemical dilution system. Without being familiar with chemical dilution systems, it can be hard to know whether or not they’ll be right for your facility.

To give you an understanding of chemical dilution systems, we’re going to explain their honest pros and cons. After reading, you’ll know whether a chemical dilution system is right for you.

What is a Chemical Dilution System?

A chemical dilution system is a machine that automatically dilutes concentrated cleaners to the correct ratio. This way, you can push a button, and your cleaning product will dispense into your spray bottle, bucket, or other equipment at the perfect dilution rate.

Chemical dilution systems can generally be used for floor cleaners, glass cleaners, carpet cleaners, bathroom cleaners, all-purpose cleaners, degreasers, sanitizers, disinfectants, and more. Offerings vary by exact system, but you can usually expect these solutions to be options for you.

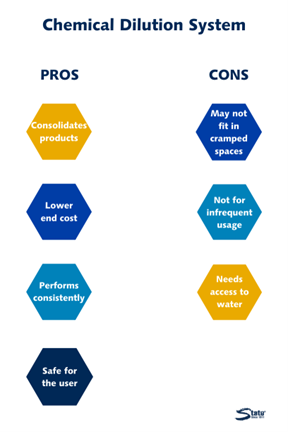

Pro: Chemical Dilution Systems Consolidate Products

One of the main perks of chemical dilution systems is the fact that they consolidate products. When you use handheld cleaners, you might have a collection of different bottles and pails cluttering your area. However, with a dilution system, it’s all confined to one area.

With this setup, you can use as many as six or more products. This can help with situations where you have frequent cleaning needs. For example, maybe you run a restaurant that frequently uses floor cleaners, glass cleaners, all-purpose cleaners, sanitizers, and disinfectants. With a dilution system, you could keep these all in one place.

However, while a dilution system can consolidate products, that is not its only intention. You can also find dilution systems that dispense as little as one chemical product. For example, imagine that you work at a fire station that frequently needs vehicle wash. In this case, it would be handy to have a chemical dilution system for vehicle wash in the garage so that you don’t have to run back and forth with heavy buckets every time.

With the different capacity options available for dilution systems, there’s a system for just about any need.

Con: Chemical Dilution Systems Don’t Work Without Access to a Water Source

An important note is that chemical dilution systems will only work in your facility if you have access to a water source where you place them. This means it’s very important that you know your setup before purchasing a system.

Maybe you want to place your dilution system in a storage closet, which is the only place you have room to store it. If you don’t have a water source in this closet, you may be at a loss. While you could surely find a water source at a different location in your facility, you may not have the space, making it the closet or nothing.

Know your setup before you invest. Without a water source, you’ll need to look at other options.

Pro: Chemical Dilution Systems Have a Lower End Cost than Handheld Cleaners

A key benefit of chemical dilution systems is that their end cost tends to be significantly lower than that of handheld cleaners.

For instance, a full spray bottle of cleaner from a chemical dilution system will usually be $0.50–$1.00. Meanwhile, a spray bottle of cleaner you’d buy without a chemical dilution system would be $2.00–$10.00. Over time, this cost difference really adds up.

Con: Chemical Dilution Systems May Not Fit in Cramped Spaces

Another important factor in your decision is the size of your space. Chemical dilution systems vary in size, but if you’re dealing with a crowded area or an oddly shaped room, they may not be the best fit (literally).

For example, if your intended location—a storage closet—is so full of shelving and equipment that there’s hardly any free wall space, a dilution system holding six cleaning products probably won’t fit. If you have a situation like this, consider whether you’ll be able to redistribute items if needed. If not, you may be better off with handheld cleaners.

Pro: Chemical Dilution Systems Perform Consistently

Another main benefit to dilution systems is that their performance will always be consistent since their concentration is always at the exact same rate. You never have to worry about a cleaner working great the first time and leaving behind residue the next.

With hand-mixed cleaners, this won’t always be the case because of the potential for human error. Someone might add too much water, leading to weak performance. Someone might not add water at all, causing a chemical hazard. People aren’t perfect, so an automated machine can take some of the worry out of chemical maintenance.

Con: Chemical Dilution Systems Aren’t Worth It If Your Chemical Use is Inconsistent

However, let’s say you aren’t using cleaning products all that much. Yes, you’re cleaning your facility, but maybe you just use two spray bottles of all-purpose cleaner a month. Maybe your business is only open two months out of the year. These are cases where using a whole dilution system might not make the most sense.

If you’re using enough chemicals frequently enough, a dilution system is the way to go. But if your usage isn’t that frequent, it might be more cost-effective to use handheld cleaners.

Pro: Chemical Dilution Systems are Safe for the User

A significant benefit of dilution systems is that they pose very little risk to the user. Where you’d have to worry about accidental contact or cross-contamination with manual mixing, dilution systems provide a safer, contact-free experience.

This means no chemical burns, hazardous fumes, or dangerous spills (although this is only if the chemicals are properly handled. You must still adhere to the usage directions on the label and information in the safety data sheet [SDS]). Through chemical dilution systems, you can foster a safer working environment.

Learn About How to Choose the Right Chemical Dilution System for Your Facility

It’s a lot of work to constantly keep your facility clean, and chemical management can just be another annoying task on your list. Now that you know the pros and cons of chemical dilution systems, continue learning how to choose the right one for your facility.